WORKING PROCESSING

Thanks to our specialized supply chain system, we guarantee clearness and traceability in every production step.

The control and separation of the processing phases, from the delivery of certified seeds to the receipt of the raw material and to the specific transformations, allow to safeguard the nutritional properties of the product and to protect the constant quality.

CEREAL PROCESSING ACTIVITIES

PRE-CLEANING PHASE

A pre-cleaning process is carried out on each raw material that enters the silos, which consists in the removal of dust and threshing residual gross substances , in order to ensure suitable storage and conservation conditions.

PRE-CLEANING PHASE

SELECTION PHASE

This operation consists in the elimination of foreign bodies and tiny and broken caryopsis, both based on weight and size through the use of cleaners, tables and vibrating screens, both based on color through an optical sorter, able to discard the grains with color defects, which could point out foreign and harmful seeds or seeds altered by mold.

This processing phase is essential to maintain the purity of our varieties and for their multiplication year after year.

SELECTION PHASE

DEHULLING PHASE

Unlike durum wheat, farro is a hulled wheat and the outer shells remain wrapped around the caryopsis even after the threshing.

Dehulling is the term used to describe the shelling process of the grain, which consists in the removal of the outer shells (glumelle) that protect the caryopsis.

DEHULLING PHASE

PEARLING PHASE

Pearled emmer wheat is obtained through a dehulling process which can be carried out with stronger or weaker intensity: the more we increase the degree of dehulling, the more the shine and brilliance of the grain increases, as the hardest and most fibrous part of the seed goes missing. A higher level of pearling allows to obtain a product that cooks in a short time, in fact the grain is able to absorb water more easily without the need of pre-soaking.

PEARLING PHASE

MILLING PHASE

Thanks to this grinding process of caryopsis of cereals, we can produce semolinas and flours. We have always used a natural stone milling, that is an ancient technique that guarantees an excellent quality result. As a matter of fact, the slow rotation of the grinder allows the entire process to work at low temperatures, which are essential to maintain the nutritional properties of farro grain or other wheats; on the contrary, high temperatures could cause enzymatic and oxidative activities.

Through the natural stone milling, we can obtain semolinas and flours rich in bran and characterized by a greater granulometry, which the germ of the grain is preserved in, rich in antioxidants, fat-soluble vitamins and essential oils.

MILLING PHASE

PACKAGING PHASE

Packaging of semi-finished products in big-bags and bags is made with food contact suitability.

PACKAGING PHASE

PASTA-MAKING PHASE

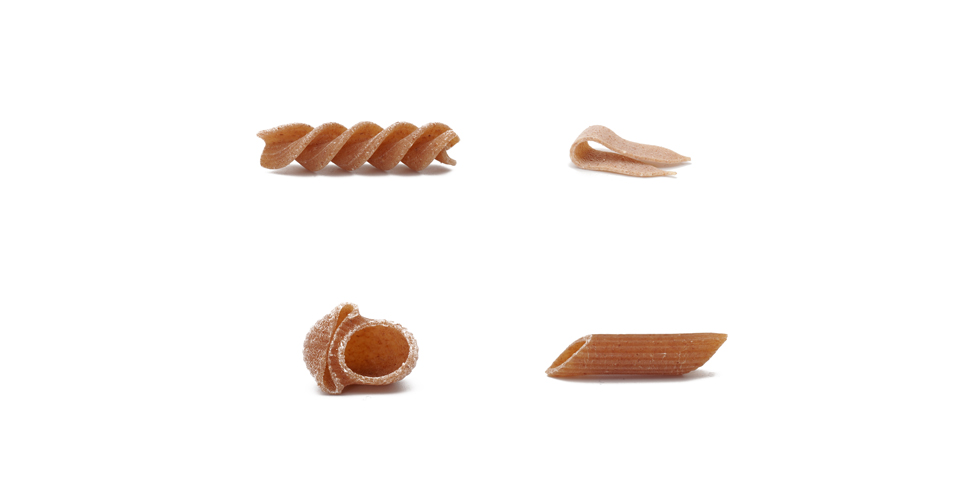

We have chosen small specialized artisan pasta factories according to each different pasta shape, able to consider the smallest details of the art of making pasta and to guarantee the quality and the good taste of the product.

Pasta making with bronze extruded, both for long and short shapes, makes porous and rough its surface, which can better absorb any type of seasoning.

PASTA-MAKING PHASE